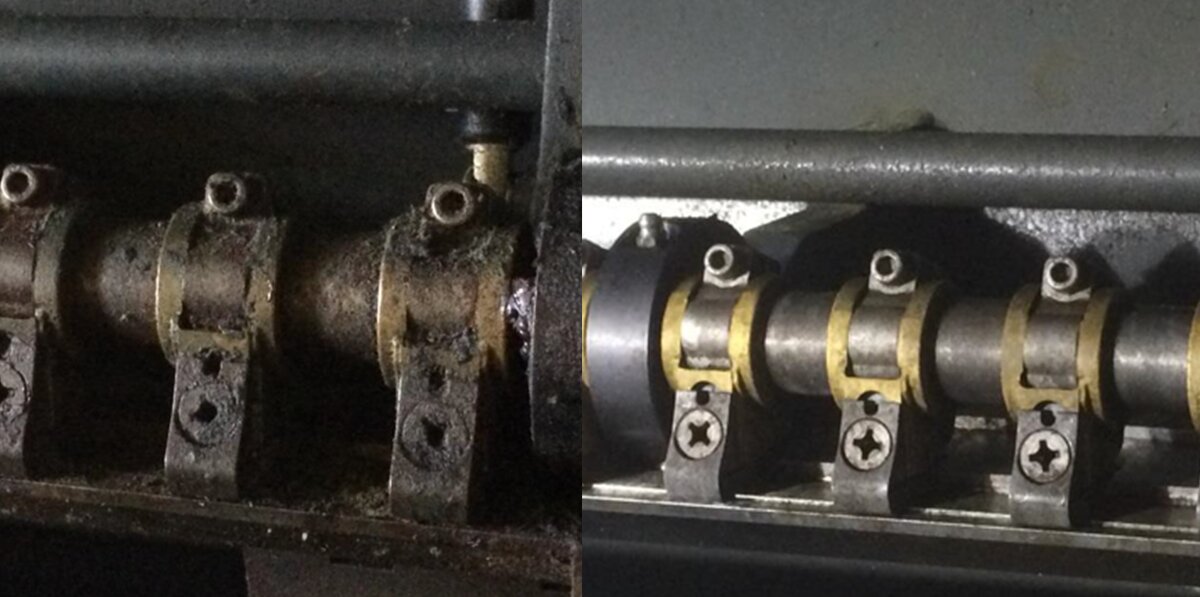

Cleaning anilox rolls for the printing press

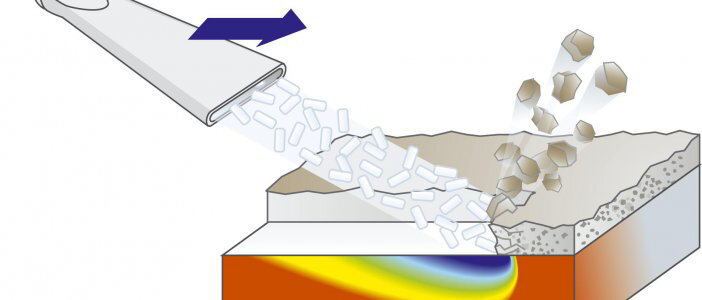

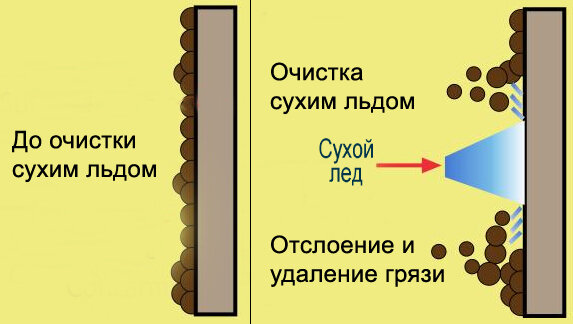

Cryogenic blasting (from Greek krýos - cold, frost, ice, from English blast - to explode) is the process of injecting pellets of dry ice under pressure of an air stream onto the surface to be cleaned.

Carbon dioxide is completely non-toxic, non-flammable and does not conduct electricity. The substance is odorless, colorless, and tasteless. The velocity is impressive, almost at the speed of sound. When hitting the surface, the carbon dioxide pellets instantly cool its top layer, so that the layer of dirt becomes brittle and fragile and comes off the surface much easier.

Advantages of such cleaning:

- Environmentally friendly cleaning - no chemicals, just ice that evaporates instantly and requires no disposal.

- No need to disassemble the equipment.

- No need to dry or cool the equipment, it is immediately ready for use.

- High quality of cleaning - pellets penetrate into corners, cracks and other hard-to-reach places which are usually very difficult to reach with a rag or brush during manual cleaning.

- Equipment does not get wet, which means you can clean even electrical equipment or other elements that do not tolerate contact with water.

- No abrasive or corrosive elements - the surface is not damaged, thinning or rusting after contact with dry ice.

-

High cleaning speed - cleaning with dry ice is many times faster than with traditional cleaning methods.

Contaminants that can be partially or completely removed with the dry ice cleaning process:

- Dried paint;

- Coatings;

- Paper dust;

- Sprayed powder;

- Lubricants;

- Oils.